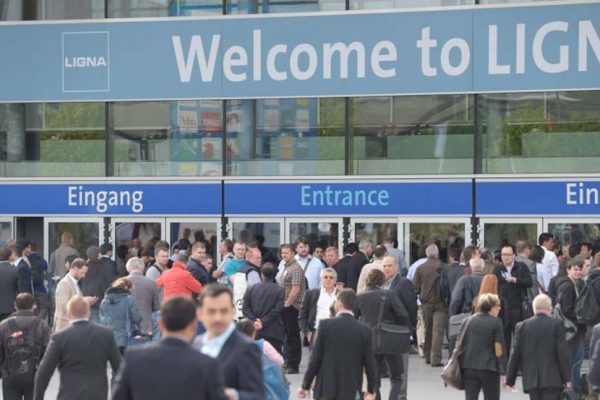

Biggest exhibition in woodworking industry is about to start in May, in Hannover. Come on board!

Over 1500 exhibitors displays huge variety of machines and tools for woodworking industry.

At the exhibition you can enjoy from a various programs provided for the visitors;

Work demonstrations with the machines, guided tours and a lot of other things offer for the visitors. The latest trends are on display at the exhibition to show the visitors how to intensify their production, how to inprove your piece handling, how to grow durability and how to make the production more versatile.

LIGNA features technology for the entire wood value chain – from harvesting machinery to industrial processing and production plant and equipment. LIGNA stands out from competing shows in that it attracts an international audience of top-level decision makers and professionals from all key sectors of the wood industry.

Contact us and arrange a meeting.

Raino Heikari, +358 408 245 332, raino.heikari@awutek.fi

Ari Jokila, +358 400 220 885, ari.jokila@awutek.fi

Kerkko Varpio, +358 400 120 207, kerkko.varpio@awutek.fi

Mika Lahtinen, +358 40 731 5830, mika.lahtinen@awutek.fi

Pekka Rasanen, +358 40 718 1488, pekka.rasanen@awutek.fi

Erik Torkko, +358 400 228 007, erik.torkko@awutek.fi

Mika Torkko, +358 40 522 7566, mika.torkko@awutek.fi

Teemu Vierimaa, +358 2 436 1115, teemu.vierimaa@awutek.fi

Jari Laine, +358 2 436 1119, jari.laine@awutek.fi

From here you can go to Ligna exhibition page.

Download here our representative list and fairground map.

See you in Ligna!!

Companies IMA Klessmann GmbH and Schelling Anlagenbau GmbH will present themselves for the first time under their new corporation name IMA Schelling Group (ISG) as well as with a new logo and Corporate Design. However, nothing has changed with the joint presentation of IMA, Schelling and Priess+Horstmann aka the “IMA Network”.

Batch-size-1 production using a fully automated and integrated production line will be the predominant theme on show at this year’s fair. IMA will once again present itself as a machine and plant manufacturer for complete solutions from one source.

New solution for panel cutting

A new flexible panel cutting cell for custom production of furniture will be one of the exhibition highlights. It will for the first time combine the panel cutting technologies from IMA and Schelling into a high-volume line with flexible cutting possibilities and panel optimisation.

Moreover, IMA will present its machines at beginners level at the Ligna 2017, for example the Novimat Contour with IMALUX – i.e. the direct laser system for truly seamless edge banding in small industrial shops – and a ›Feedback‹ return conveyor. The new features of the high-volume drilling machine ›IMAGIC Flex‹ will also be presented. And last but not least, the IMA Service will be represented with its own booth at the Ligna fair.

Read the full Ligna press release from here.

IMA, Schelling and Priess+Horstmann the “IMA Network” will be displayed on a common, 3608 m² large exhibition stand (Hall 12 / Stands A 50 – E 50).

The Weinig Group at LIGNA 2017: Digitized production at the customer’s service

LIGNA 2017 will open with a new space concept. This means that, for the first time, the Weinig Group will be presenting its complete range for solid wood and panel processing in Hall 27. The 4000 m2 stand will pro-vide customers with a unique offering for small business and industry under the motto “THINK WEINIG”. The solid wood processing area will present the product range from the planing and profiling, cutting and op-timization, jointing technology and window & furniture production seg-ments. W 4.0 Digital, project business and alternative materials will all be under the spotlight.

The Weinig Powermat world

In the Powermat, Weinig has created a modular system that fulfills these precise requirements. The new Powermat 2400 will celebrate its world premiere at LIGNA. The moulder is designed for industrial bead produc-tion at feed speeds up to 100 m/min and will be demonstrated in a mech-anized process with charging and discharge. The 3D version can pro-duce freely-programmable structured surfaces during throughfeed. A new feature is the facility to produce work pieces with conical or curved contours on the machine. For newcomers to the world of Weinig profil-ing, we have the Powermat 700 Compact. A window version is availa-ble in the same performance category for planing scantlings and profiling mouldings. On the next level, the Powermat 1500 is available in a wide range of variants covering various requirements and applications. Whether producing different widths with a mobile spindle or small batch sizes on one and the same machine, the Powermat 1500 is a moulder for all occasions. The Powermat 2500 SP splitting unit equipped with kerf saws for separating lamellae, as used in central layer production for ex-ample, completes the Weinig Powermat world.

Read the full Weinig Ligna press release from here.

See Weinig stand layout and all the machines.

Weinig Group in hall 27.

MARTIN has every reason to celebrate this year: For more than 95 years the name MARTIN has stood for premium-class woodwork-ing machinery. What Otto Martin, the founder, had started in 1922 with basic and solid machinery, eventually developed to become a benchmark for quality and functionality in the woodworking ma-chinery sector over the following nearly 100 years. Ground breaking innovations and numerous awards and patents date back to our traditional company from the Allgäu region of Germany. MARTIN has shaped the production environment of workshops and industrial enterprises worldwide.

Martin is at hall 12, stand E30.

Surface treatment by Superfici

Superfici machinery will be displayed in Hall 16 at the Ligna 2017 fair, offering advanced solutions for painting panels, furniture parts and window and door frames, and focusing on flexibility and the use of latest-generation painting cycles. Heading the collection is Bravorobot, a painting robot system with a three-dimensional control of workpieces, for quality spraying of panels and even of custom shapes and complex edges. The Maestro robot is a first-rate complete solution for painting door and window frames. Especially noteworthy are the UV Led Matrix systems, marking the new frontier of UV curing, a smart choice in terms of energy consumption savings.

Superfici is at Hall 16, Stand C06.

Costa will exhibit at next LIGNA Exhibition which will be held in Hannover (Germany) from 22th to 26th may 2017.

We will show following representative machines of our production range; all of them will be working and you will have the

possibility to carry out some processing tests, if wished.

Costa is in Hall 6, Stand A14.

Masterwood will be present at LIGNA 2017 where our technical and commercial staff will be at your complete disposal to give demonstrations on all our machines.

Here is a short description of the new machines which will be exhibited.

Masterwood is in Hall 12, Stand E78.